| Services Available | |

|---|---|

| Repair | Yes |

| Calibration | No |

| Free Support | Yes |

Overview

The CR216X is a small, low-cost datalogger that includes an internal 2.4 GHz spread-spectrum radio for transmitting data to another CR216(X), an RF416 radio, or RF432 radios. The 2.4 GHz frequency can be used worldwide.

The CR216X provides stand-alone operation in harsh, remote environments. It reads input from one or two sensors, then transmits its data wirelessly via its internal radio. Multiple CR216Xs can be configured as a network, or units can be deployed individually.

Read MoreBenefits and Features

- Small, low-cost data logger with internal spread spectrum radio for wireless communications

- Integrated radio lets this data logger function like a wireless sensor in a network, transmitting to a master data logger

- Ideal applications include wind energy, rural water, water level/flow, aquaculture, water quality

- Gas Discharge Tube (GDT) protected inputs

- Optimal for measuring one or two simple sensors

- Makes SDI-12, single-ended analog, pulse, switch closure, and bridge measurements

- Battery-backed clock that ensures accurate time is maintained while data logger is disconnected from battery power

- Program with LoggerNet, PC400, or Short Cut to fit your setup

- PakBus, Modbus, and SDI-12 protocols supported

Images

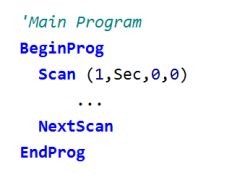

Technical Description

The CR216X can be used in a wireless sensor network. Wireless sensor networks are appealing because they are often more economical than trenching, laying conduit, and pulling wire. When used as a wireless sensor, the CR216X measures the sensors attached to it, then transmits its data wirelessly via its spread-spectrum radio to a master datalogger. The master datalogger must use the PakBus communication protocol (e.g., CR800,CR850, CR1000, CR3000). For more information on how to configure a PakBus system, please read our PakBus Networking Guide (see sidebar).

The CR216X has several input channels for measuring a variety of sensors. Gas discharge tubes provide rugged electrostatic discharge protection for the inputs.

The CR216X does not make differential measurements and is not compatible with SDM devices, multiplexers, or thermocouples (refer to the Compatibility tab for compatible sensors, peripherals, and software). Recalibration services are not offered for the CR216X dataloggers.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Sensors

| Product | Compatible | Note |

|---|---|---|

| 03002-L | ||

| 034B-L (retired) | ||

| 05103-L | ||

| 109-L | ||

| 110PV-L (retired) | ||

| CMP11-L (retired) | ||

| CS215-L (retired) | ||

| CS300-L (retired) | ||

| CS451-L | ||

| CS456-L | ||

| HC2S3-L (retired) | ||

| ICEFREE3A (retired) | ||

| ICEFREE3V (retired) | ||

| TB4-L | ||

| TE525-L |

Software

| Product | Compatible | Note |

|---|---|---|

| LoggerNet | Version 2.1 or higher | |

| PC400 | Version 1.0 or higher | |

| Short Cut |

Miscellaneous

| Product | Compatible | Note |

|---|---|---|

| 014A-L | ||

| 03101-L (retired) | ||

| 05103-45-L (retired) | ||

| 05106-L (retired) | ||

| 05305-L | ||

| 083E-L (retired) | ||

| 107-L | ||

| 108-L | ||

| 109SS-L | ||

| 237-L (retired) | ||

| 255-100 | ||

| 27106T-L | ||

| 43347-L | ||

| 52202-L | ||

| A100LK-L | ||

| CMP21-L | ||

| CMP3 (retired) | ||

| CMP6-L | ||

| CS106 | ||

| CS11-L (retired) | ||

| CS410-L (retired) | ||

| CS460-L (retired) | ||

| CS470 (retired) | ||

| CS471 (retired) | ||

| CS475A-L | ||

| CS475-L (retired) | ||

| CS511-L (retired) | ||

| CS526-L (retired) | ||

| CS547A-L | ||

| CS616-L | ||

| CS625-L (retired) | ||

| CS650-L | ||

| CS655-L | ||

| CS700-L | ||

| CSAT3 (retired) | ||

| CSIM11-L (retired) | ||

| CSIM11-ORP-L (retired) | ||

| ENVIROSCAN (retired) | ||

| HMP155A-L | ||

| HMP60-L | ||

| LI190SB-L (retired) | ||

| LI200X-L (retired) | ||

| LWS | ||

| OBS-3+ (retired) | ||

| OBS300 (retired) | ||

| OBS500 (retired) | ||

| PC200 (retired) | ||

| PCONNECT (retired) | ||

| PCONNECTCE (retired) | Version 2.0 or higher | |

| SEN12512 (retired) | ||

| SR50A-L (retired) | ||

| TB4MM-L | ||

| TE525MM-L | ||

| VISUALWEATHER | Version 2 or higher | |

| WINDSONIC1-L | ||

| WINDSONIC4-L | ||

| WXT520 (retired) |

Additional Compatibility Information

Communications

The CR216X can communicate with a PC via direct connect, NL201 Network Link Interface, NL240 Wi-Fi Network Link, MD485 multidrop modem, and digital cellular modems. Data can be viewed on an iOS device, an Android device, CD295 DataView II Display, or a user-supplied PDA. To use an iOS or Android device, go to the Apple Store or Google Play and download our LoggerLink Mobile Apps free of charge. User-supplied PDAs require either PConnect or PConnectCE software.

The CR216X's internal spread spectrum radio can transmit data to other CR216(X) loggers, RF416 radios, or RF430 radios. Certain CR216X settings must match the radio's settings for communications between the data logger and radio to be successful. The factory default settings of these devices might not match; therefore, they may need to be reconfigured before communications can take place.

If the CR216X is in the transparent mode, it can communicate with the retired CR215 loggers or RF415 radios.

Measurement & Control Peripherals

Campbell Scientific’s SDM devices and multiplexers are not supported.

Sensors

The CR216X can measure a variety of sensors including SDI-12 sensors and 4 to 20 mA sensors. It cannot make differential measurements and is not compatible with the freezing-rain/ice, fuel moisture/temperature, geographic position, present weather, soil heat flux, soil matric water potential, and strain sensors listed on our price lists.

Enclosures

Applications with minimal power requirements can use the ENC200 enclosure to house the data logger and the #16869 sealed rechargeable battery. The ENC200 cannot house a barometer or a battery that is larger than the #16869. However, an ENC10/12 or ENC12/14 enclosure is adequate for most CR216X-based systems.

Power Supplies

The CR216X uses an external power supply and has a built-in regulator. When connected to the on-board charging circuit, the sealed rechargeable battery should be 7 A h or smaller. Using larger batteries with the data logger's built-in charger may result in excessive PC board heating. This is especially a concern when the battery is deeply discharged or failing with a shorted cell. Campbell Scientific also recommends that solar panels be 10 W or less and wall chargers be 1 A or smaller.

Specifications

| -NOTE- | Note: Additional specifications are listed in the CR200X-Series Specifications Sheet. |

| Internal Spread-Spectrum Radio Operating Frequency Range | 2.450 to 2.482 GHz |

| Transmitter Power Output | 50 mW |

| Maximum Scan Rate | 1 Hz |

| Analog Channels |

|

| Pulse Count Channels | 2 |

| Switched Excitation Channels | 2 voltage |

| Digital Ports |

|

| Communication Ports | 1 RS-232 |

| Switched Battery Port | 1 |

| Input Voltage Range | 0 to 2500 mV |

| Analog Voltage Accuracy | ±(0.25% of reading + (1.2 mV)x(offset)) at -40° to +50°C |

| Analog Voltage Resolution | 0.6 mV |

| A/D Bits | 12 |

| Operating Temperature | -40° to +50°C |

| Power Requirements | 7 to 16 Vdc |

| Typical Current Drain |

|

| Clock Accuracy |

|

| Protocols Supported | PakBus (leaf node only), SDI-12 |

| CE Compliance Standards to which Conformity Is Declared | IEC61326:2002 |

| Warranty | 3 years |

| Dimensions | 14.0 x 7.6 x 4.8 cm (5.5 x 3.0 x 1.9 in.) |

| Weight | 271 g (9.5 oz) |

Memory |

|

| Final Storage | 512 kB of flash memory for approximately 125,000 data points |

| Operating System | 106 kB of flash memory |

| Intermediate Storage | 8 kB of SRAM for communication buffers, calculations, variables, etc. |

Related Documents

Product Brochures

Technical Papers

Miscellaneous

Downloads

CR200X Series OS v.04 (1.29 MB) 22-09-2015

Execution of this download installs the Operating System and Compiler on your computer for the following dataloggers:CR200X, CR206X, CR211X, CR216X and CR295X. It also updates the support files for the CRBasic Editor.

Note: Newer CR206X dataloggers (serial # ≥ 19122) and newer CR211X dataloggers (serial # ≥ 19143) have 250 mW radios that must use OS 3 or higher for their datalogger operating system.

Related FAQs

Number of FAQs related to CR216X: 38

Expand AllCollapse All

-

One of the simpler ways to approximate how long it will take for a data table to fill up is to open the LoggerNet Connect screen, click the Station Status button, and view the Table Fill Times tab.

-

Not directly. If the CS15-L is connected to a CR200(X) datalogger, the datalogger can take the ac measurement and control a solid-state relay based on some threshold within the datalogger program. The solid-state relay can then control other relays, solenoids, or motor starters. (Use of a solid-state relay is preferred because the datalogger can trigger it with a small 5 Vdc mA signal.) For more information, see the “Measurement and Control Peripherals” section of the operator’s manual.

-

Technically, the SRM-5A is compatible with the CR200X-series dataloggers, but it is more complicated to use it with these dataloggers. To use a SRM-5A with a CR200X-series datalogger, the SRM-5A must be in the DTE position on the station modem. In addition, user-supplied adapters and gender changers are needed to complete the connections between the SRM-5A and the RS-232 port of the datalogger. Contact Campbell Scientific for more information.

-

The maximum cable length depends on the interface being used.

- RS-232 connections will reach 15 m (50 ft).

- RS-485 connections go beyond 610 m (2,000 ft).

- IP connections can be routed worldwide.

-

Yes, but only with a direct connection, such as an RS-232 cable or a USB-to-serial adapter. While connected to the datalogger, press the Send Program button on the Clock\\Program tab, and browse to the program file.

-

In the CRBasic program, set up multiple data tables using the DataTable() instruction. In each table, specify the desired output interval using the DataInterval() instruction.

For example, the following three table definitions could be included in a program to store values once a day, once an hour, and every minute.

DataTable (Daily,1,1000)

DataInterval (0,24,Hr,10)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,PTemp,FP2)

EndTableDataTable (Hourly,1,1000)

DataInterval (0,1,Hr,10)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,PTemp,FP2)

EndTableDataTable (OneMinute,1,1000)

DataInterval (0,1,Min,10)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,PTemp,FP2)

EndTableNote: The shortest interval at which the CR200X-series dataloggers can store data is once every minute.

-

Current dataloggers compatible with the BMP5 Direct SDK are the CR200X-series, CR1000, CR3000, CR800, and CR850.

Retired compatible dataloggers include the CR10X-PB, CR23X-PB, and CR510-PB. These dataloggers must have the optional PakBus operating system installed, which is available on the Downloads page of our website.

-

The CRBasic Editor Help contains example program code for all instructions in the datalogger. Look for the Example link at the top of each instruction topic. The CRBasic Help Tutorial demonstrates how to access this and other online CRBasic Editor Help files.

Also, many programming examples can be found in the datalogger and sensor manuals that are available on the Campbell Scientific website.

-

Some Campbell Scientific sensors with an RS-232 output are supported in Short Cut. Because of the large variety of serial data formats, other sensors require creating a program in the CRBasic Editor. CRBasic Editor is included in several of the purchased software packages, such as LoggerNet. For more information, see the “Interfacing Serial Sensors with Campbell Scientific Dataloggers” application note.

Note: The CR200X-series dataloggers have very limited serial capabilities.

-

Yes. The simplest method is to use conditional program statements that execute most of the code based on time. For example, the data could be scheduled to log at 6 a.m. and finish at 8 p.m. using CRBasic instructions such as IfTime(). Another option is to use an IfThen/EndIf construction that does a logical test of light-level measurements based on a light sensor. An additional option is to use calculated sunrise and sunset times along with a combination of RealTime() and Case instructions.

For more information, see the “Decisions, Decisions, Decisions…” article.