More accurate in soils with high bulk electrical conductivity

Overview

The CS650 is a multiparameter smart sensor that uses innovative techniques to monitor soil volumetric water content, bulk electrical conductivity, and temperature. It outputs an SDI-12 signal that many of our dataloggers can measure.

Read MoreBenefits and Features

- More accurate water content measurements in soils with bulk EC up to 3 dS m-1 without performing a soil-specific calibration

- Larger sample volume reduces error

- Measurement corrected for effects of soil texture and electrical conductivity

- Estimates soil-water content for a wide range of mineral soils

- Versatile sensor—measures dielectric permittivity, bulk electrical conductivity (EC), and soil temperature

Images

Related Products

Technical Description

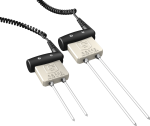

The CS650 consists of two 30-cm-long stainless steel rods connected to a printed circuit board. The circuit board is encapsulated in epoxy and a shielded cable is attached to the circuit board for datalogger connection.

The CS650 measures propagation time, signal attenuation, and temperature. Dielectric permittivity, volumetric water content, and bulk electrical conductivity are then derived from these raw values.

Measured signal attenuation is used to correct for the loss effect on reflection detection and thus propagation time measurement. This loss-effect correction allows accurate water content measurements in soils with bulk EC ≤3 dS m-1 without performing a soil specific calibration.

Soil bulk electrical conductivity is also calculated from the attenuation measurement. A thermistor in thermal contact with a probe rod near the epoxy surface measures temperature. Horizontal installation of the sensor provides accurate soil temperature measurement at the same depth as the water content. Temperature measurement in other orientations will be that of the region near the rod entrance into the epoxy body.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

RF Considerations

External RF Sources

External RF sources can affect the probe’s operation. Therefore, the probe should be located away from significant sources of RF such as ac power lines and motors.

Interprobe Interference

Multiple CS650 sensors can be installed within 4 inches of each other when using the standard datalogger SDI-12 “M” command. The SDI-12 “M” command allows only one probe to be enabled at a time.

Installation Tool

The CS650G makes inserting soil-water sensors easier in dense or rocky soils. This tool can be hammered into the soil with force that might damage the sensor if the CS650G were not used. It makes pilot holes into which the rods of the sensors can then be inserted.

Specifications

| Measurements Made | Soil electrical conductivity (EC), relative dielectric permittivity, volumetric water content (VWC), soil temperature |

| Required Equipment | Measurement system |

| Soil Suitability | Long rods with large sensing volume (> 6 L) are suitable for soils with low to moderate electrical conductivity. |

| Rods | Not replaceable |

| Sensors | Not interchangeable |

| Sensing Volume | 7800 cm3 (~7.5 cm radius around each probe rod and 4.5 cm beyond the end of the rods) |

| Electromagnetic |

CE compliant Meets EN61326 requirements for protection against electrostatic discharge and surge. |

| Operating Temperature Range | -50° to +70°C |

| Sensor Output | SDI-12; serial RS-232 |

| Warm-up Time | 3 s |

| Measurement Time | 3 ms to measure; 600 ms to complete SDI-12 command |

| Power Supply Requirements | 6 to 18 Vdc (Must be able to supply 45 mA @ 12 Vdc.) |

| Maximum Cable Length | 610 m (2000 ft) combined length for up to 25 sensors connected to the same data logger control port |

| Rod Spacing | 32 mm (1.3 in.) |

| Ingress Protection Rating | IP68 |

| Rod Diameter | 3.2 mm (0.13 in.) |

| Rod Length | 300 mm (11.8 in.) |

| Probe Head Dimensions | 85 x 63 x 18 mm (3.3 x 2.5 x 0.7 in.) |

| Cable Weight | 35 g per m (0.38 oz per ft) |

| Probe Weight | 280 g (9.9 oz) without cable |

Current Drain |

|

| Active (3 ms) |

|

| Quiescent | 135 µA typical (@ 12 Vdc) |

Electrical Conductivity |

|

| Range for Solution EC | 0 to 3 dS/m |

| Range for Bulk EC | 0 to 3 dS/m |

| Accuracy | ±(5% of reading + 0.05 dS/m) |

| Precision | 0.5% of BEC |

Relative Dielectric Permittivity |

|

| Range | 1 to 81 |

| Accuracy |

|

| Precision | < 0.02 |

Volumetric Water Content |

|

| Range | 0 to 100% (with M4 command) |

| Water Content Accuracy |

|

| Precision | < 0.05% |

Soil Temperature |

|

| Range | -50° to +70°C |

| Resolution | 0.001°C |

| Accuracy |

|

| Precision | ±0.02°C |

Related Documents

Downloads

CS650 / CS655 Firmware v.2 (429 KB) 02-12-2015

Current CS650 and CS655 firmware.

Note: The Device Configuration Utility and A200 Sensor-to-PC Interface are required to upload the included firmware to the sensor.

Related FAQs

Number of FAQs related to CS650-L: 53

Expand AllCollapse All

-

The permittivity of saturated sediments in a stream bed is expected to read somewhere between 25 and 42, while the permittivity of water is close to 80. A CS650-L or CS655-L installed in saturated sediments could be used to monitor sediment erosion. If the permittivity continuously increases beyond the initial saturated reading, this is an indication that sediment around the sensor rods has eroded and been replaced with water. A calibration could be performed that relates permittivity to the depth of the rods still in the sediment.

-

The CS650-L and CS655-L are warranted by Campbell Scientific to be free from defects in materials and workmanship under normal use and service for 12 months from the date of shipment. For further details, see the “Warranty” section of the CS650/CS655 manual.

-

No. The principle that makes these sensors work is that liquid water has a dielectric permittivity of close to 80, while soil solid particles have a dielectric permittivity of approximately 3 to 6. When liquid water freezes, its dielectric permittivity drops to 3.8, essentially making it look like soil particles to the sensor. A CS650-L or CS655-L installed in soil that freezes would show a rapid decline in its volumetric water content reading with corresponding temperature readings that are below 0°C. As the soil freezes down below the measurement range of the sensor, the water content values would stop changing and remain steady for as long as the soil remains frozen.

-

No. The abrupt permittivity change at the interface of air and saturated soil causes a different period average response than would occur with the more gradual permittivity change found when the sensor rods are completely inserted in the soil.

For example, if a CS650-L or a CS655-L was inserted halfway into a saturated soil with a volumetric water content of 0.4, the sensor would provide a different period average and permittivity reading than if the probe was fully inserted into the same soil when it had a volumetric water content of 0.2.

-

The dielectric of water at room temperature is close to 80. The firmware for both the CS650-L and the CS655-L is programmed to change volumetric water content to NAN or 9999999 when the permittivity measurements are greater than 42. When testing in water, look at the permittivity reading rather than the water content reading. If a test is being done for functionality, pull the sensor about halfway out of the water to see both permittivity and volumetric water content readings.

-

The volumetric water content reading is the average water content over the length of the sensor’s rods.

-

Because the reported volumetric water content reading is an average taken along the entire length of the rods, the sensor should be fully inserted into the soil. Otherwise, the reading will be the average of both the air and the soil, which will lead to an underestimation of water content. If the sensor rods are too long to go all the way into the soil, Campbell Scientific recommends inserting the rods at an angle until they are fully covered by soil.

-

The CS650-L and the CS655-L are not ideal sensors for measuring water level. However, these sensors do respond to the abrupt change in permittivity at the air/water interface. A calibration could be performed to relate the period average or permittivity reading to the distance along the sensor rods where the air/water interface is located. From that, the water level can be determined. The permittivity of water is temperature dependent, so a temperature correction would be needed to acquire accurate results.

-

Some customers have successfully used water content reflectometers, such as the CS650-L and the CS655-L, to measure water content of wet concrete mix to ensure consistency between different batches of concrete. However, after concrete begins the curing process, salts are formed that make the electrical conductivity too high for the CS650-L and the CS655-L to operate. Thus, these sensors cannot be embedded in wet concrete to measure the water content of the concrete as it cures and dries.

-

No. The equation used to determine volumetric water content in the firmware for the CS650-L and the CS655-L is the Topp et al. (1980) equation, which works for a wide range of mineral soils but not for organic soils. In organic soils, the standard equations in the firmware will overestimate water content.

When using a CS650-L or a CS655-L in organic soil, it is best to perform a soil-specific calibration. For details on performing a soil-specific calibration, refer to “The Water Content Reflectometer Method for Measuring Volumetric Water Content” section in the CS650/CS655 manual. A linear or quadratic equation that relates period average to volumetric water content will work well.

Case Studies

Everglades National Park is the largest tropical wilderness in the United States and was created......read more