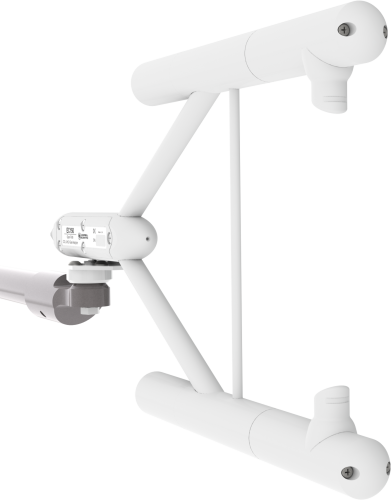

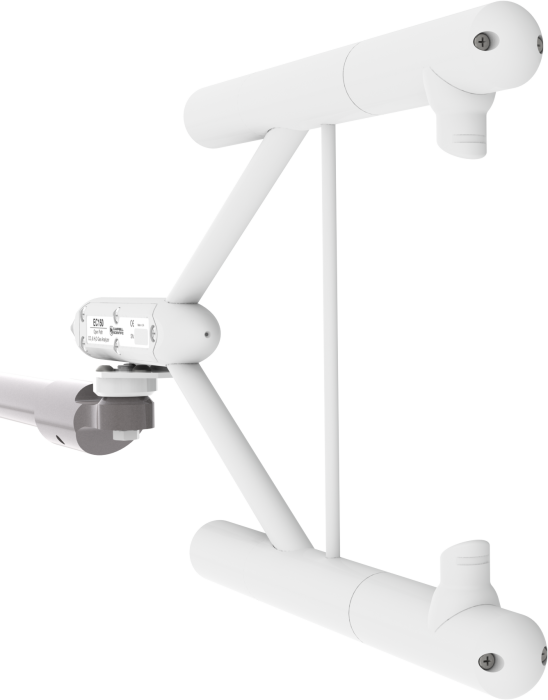

Use as part of open-path eddy-covariance systems or as a stand-alone IRGA

Overview

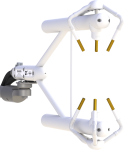

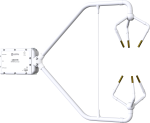

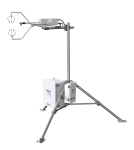

Campbell Scientific’s EC150 is an open-path analyzer specifically designed for eddy-covariance flux measurements. As a stand-alone analyzer, it simultaneously measures absolute carbon-dioxide and water-vapor densities, air temperature, and barometric pressure. With the optional CSAT3A sonic anemometer head, the EC150 also measures three-dimensional wind speed and sonic air temperature.

Read MoreBenefits and Features

- New conformal coating helps protect sonic transducers in corrosive environments

- Unique optical configuration gives a slim aerodynamic shape with minimal wind distortion

- Analyzer and sonic anemometer measurements are synchronized by a common set of electronics

- Maximum output rate of 60 Hz with 20 Hz bandwidth

- Low power consumption; suitable for solar power applications

- Low noise

- Measurements are temperature compensated without active heat control

- Angled windows to shed water and are tolerant to window contamination

- Field rugged

- Field serviceable

- Factory calibrated over wide range of CO2, H2O, pressure, and temperature in all combinations encountered in practice

- Extensive set of diagnostic parameters

- Fully compatible with Campbell Scientific dataloggers; field setup, configuration, and field zero and span can be accomplished directly from the datalogger

- Speed of sound determined from three acoustic paths; corrected for crosswind effects

- Innovative signal processing and transducer wicks considerably improve performance of the anemometer during precipitation events

Images

Related Products

Technical Description

The EC150 has the following outputs:

- Ux (m/s)*

- Uy (m/s)*

- Uz (m/s)*

- Sonic Temperature (°C)*

- Sonic Diagnostic*

- CO2 Density (mg/m3)

- H2O Density (g/m3)

- Gas Analyzer Diagnostic

- Ambient Temperature (°C)

- Atmospheric Pressure (kPa)

- CO2 Signal Strength

- H2O Signal Strength

*The first five outputs require the CSAT3A Sonic Anemometer Head.

Specifications

| Operating Temperature Range | -30° to +50°C |

| Calibrated Pressure Range | 70 to 106 kPa |

| Input Voltage Range | 10 to 16 Vdc |

| Power | 5 W (steady state and power up) at 25⁰C |

| Measurement Rate | 60 Hz |

| Output Bandwidth | 5, 10, 12.5, or 20 Hz (user-programmable) |

| Output Options | SDM, RS-485, USB, analog (CO2 and H2O only) |

| Auxiliary Inputs | Air temperature and pressure |

| Gas Analyzer/Sonic Volume Separation | 5.0 cm (2.0 in.) |

| Warranty | 3 years or 17,500 hours of operation (whichever comes first) |

| Cable Length | 3 m (10 ft) from EC150 and CSAT3A to EC100 |

| Weight |

|

Gas Analyzer |

|

| Path Length |

15.37 cm (6.05 in.)

A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

Gas Analyzer - CO2 Performance |

|

| -NOTE- | A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

| Accuracy |

|

| Precision RMS (maximum) |

0.2 mg/m3 (0.15 µmol/mol)

Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth. |

| Calibrated Range | 0 to 1,000 μmol/mol (0 to 3,000 µmol/mole available upon request.) |

| Zero Drift with Temperature (maximum) | ±0.55 mg/m3/°C (±0.3 μmol/mol/°C) |

| Gain Drift with Temperature (maximum) | ±0.1% of reading/°C |

| Cross Sensitivity (maximum) | ±1.1 x 10-4 mol CO2 /mol H2O |

Gas Analyzer - H2O Performance |

|

| -NOTE- | A temperature of 20°C and pressure of 101.325 kPa was used to convert mass density to concentration. |

| Accuracy |

|

| Precision RMS (maximum) |

0.004 g/m3 mmol/mol (0.006 mmol/mol) Nominal conditions for precision verification test: 25°C, 86 kPa, 400 μmol/mol CO2, 12°C dewpoint, and 20 Hz bandwidth. |

| Calibrated Range | 0 to 72 mmol/mol (38°C dewpoint) |

| Zero Drift with Temperature (maximum) | ±0.037 g/m3/°C (±0.05 mmol/mol/°C) |

| Gain Drift with Temperature (maximum) | ±0.3% of reading/°C |

| Cross Sensitivity (maximum) | ±0.1 mol H2O/mol CO2 |

Sonic Anemometer - Accuracy |

|

| Offset Error |

|

| Gain Error |

|

| Measurement Precision RMS |

|

| Speed of Sound | Determined from 3 acoustic paths (corrected for crosswind effects) |

| Rain | Innovative ultrasonic signal processing and user-installable wicks considerably improve the performance of the anemometer under all rain events. |

Ambient Temperature |

|

| Manufacturer | BetaTherm 100K6A1IA |

| Total Accuracy | ±0.15°C (-30°C to +50°C) |

| EC100 ingress protection | IP65 |

Related Documents

Manuals

Technical Papers

Miscellaneous

- Improved Flux Measurements from Campbell Scientific Open-Path Gas Analyzers: Utilizing Sonic Temperature to Account for Spectroscopic Effects on CO2 Density

- Influence of Open-path Gas Analyzer Flow Distortion on Ultrasonic Wind Measurements

- Using Molecular Sieve to Zero Infrared Gas Analyzers for Eddy Covariance or Atmospheric Profile Measurements

Downloads

EasyFlux DL for CR6OP v.2.02 (99.2 KB) 31-10-2025

CR6 datalogger program for Campbell open-path eddy-covariance systems.

ECMon v.1.6 (10.7 MB) 29-03-2016

EC100-Series Support Software.

EC100 OS v.8.02 (560 KB) 14-10-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

Device Configuration Utility v.2.33 (49.6 MB) 07-07-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

Related FAQs

Number of FAQs related to EC150: 21

Expand AllCollapse All

-

The molecular sieve is a non-hazardous material that can be shipped to any country.

-

The molecular sieve has been demonstrated here by our engineering department to be effective at removing CO2 and H2O from the air sample. The change was made for two reasons:

- It was a safer alternative than using the previous chemicals.

- Increased shipping regulations for the chemicals limited the number of suppliers.

-

The molecular sieve is a direct replacement for the old magnesium perchlorate bottles. The molecular sieve may be used for any Campbell Scientific analyzer that used the old bottles.

-

The factory calibration accounts for CO2 and H2O signal strengths down to 0.7. Therefore, to ensure quality data, windows should be cleaned before signal strengths drop below 0.7.

-

The bottles of sieve for drop-in replacement contain the pellets and a membrane on top. The membrane is necessary to keep the pellets contained while allowing gas to pass over the zeolite. The bottle has the same footprint as the old magnesium perchlorate bottles. The amount in each bottle is listed on the bottle. The amount of sieve needed for each analyzer is the following:

- The EC150 needs 22 g (drop-in bottle).

- The IRGASON® needs 22 g (drop-in bottle).

- The EC155 needs 22 g (drop-in bottle).

- The AP200 needs 500 g (refill).

- The 27423 needs 1000 g (refill).

- The 31022 needs 500 g (refill).

-

Differences between the sonic calculated temperature and the air temperature measured by a more traditional sensor do not necessarily indicate a problem. Sonic anemometers, because of their high sensitivities to sonic geometry and transducer response time, do not typically measure absolute temperature as accurately as traditional temperature probes. Even very small changes in geometry can lead to errors in sonic temperature because sonic temperature is proportional to the square of any error in the distance between sonic transducers. As an example, a change of only 200 micrometers in sonic path length at room temperature yields a 1°C change in measured sonic temperature.

Even though sonic anemometers are generally not recommended for measuring absolute temperature, they excel at measuring fast temperature fluctuations, which are needed for eddy-covariance calculations (sensible heat flux). Furthermore, the error in sonic temperature in most cases can be regarded as an offset after sonic temperature has been corrected for humidity, and therefore, it will not have an effect on the covariance calculation. Nevertheless, if a user desires to calibrate the sonic temperature to account for this offset, this can be done using the temperature reading from a collocated temperature probe, such as the EC150 or IRGASON temperature probe.

-

For greatest accuracy, Campbell Scientific recommends that a zero and a span be done on the EC150 or IRGASON. However, if a span gas is difficult to obtain, at the minimum, perform a zero on the analyzer. Performing a zero will correct the majority of drift experienced by the analyzer. Follow the zero procedure in the analyzer’s manual for details.

-

Yes. A fine-wire thermocouple, such as a FW05, can be used.

-

Selecting which barometer to use is the choice of the user. There is a direct correlation between the accuracy level of the barometer and its cost.

- The basic barometer has an accuracy of ±1.5 kPa between 0° and 50°C. Below 0°, the error increases linearly to ±3.7 kPa at -30°C.

- The enhanced barometer offers an accuracy of ±0.15 kPa (-30° to +50°C).

When choosing a barometer, consider the effect of pressure accuracy on flux calculations. For sensible heat flux, the barometric pressure is used to calculate the density of air, which directly scales the sensible heat flux. Therefore, if the barometric pressure measurement is off by 1%, then the sensible heat flux will be off by 1%.

For CO2 flux, the EC150 and IRGASON report CO2 as density. Thus, the barometric pressure is not used to directly calculate the flux. However, error in pressure measurements could cause an error in CO2 flux resulting from a CO2 span. During the span procedure, the user enters the “true CO2 value” as a CO2 concentration, which is later converted to density using the barometric pressure. Consequently, the error in CO2 measurements is directly proportional to the error in the barometric pressure measurement.

-

The minimum height for the IRGASON or EC150 should be approximately 2 m. Sensor placement below that height may result in a significant loss in frequency response. The maximum height depends on the available upwind fetch or footprint area. As a general guideline for unstable boundary layer conditions, the height of the sensor should be less than the distance from the sensor to the outermost edge of the footprint area divided by one hundred. For example, if there is 500 m of available upwind fetch, the IRGASON or EC150 should not exceed a height of 5 m. Note that for neutral and stable conditions, the footprint area will grow.

Articles and Press Releases

Case Studies

Scientists and land-use managers have long recognized the importance of forest lands for their role......read more