Manages voltage and amperage to protect battery

Overview

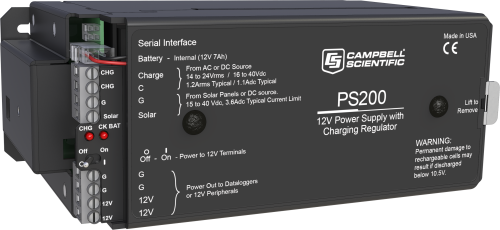

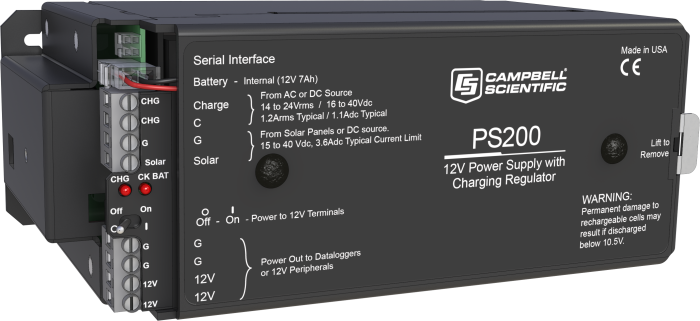

The PS200 is a 12-Vdc battery with a charge controller. The controller manages amperage and voltage for safe, optimized battery charging from a solar-panel or AC power source. It also measures various input, output, and status parameters to allow close monitoring of the battery during charging and use. The PS200 includes a 12-Vdc lead-acid battery, while the CH200 is for use with a user-supplied battery.

Read MoreBenefits and Features

- Protects against high-amperage and high-voltage damage to power supply

- Ability to monitor both load and battery current

- Battery reversal protection

- Real-time measurements of charge input voltage, battery voltage, on-board temperature, battery current, and load current

- Two-step constant voltage charging and temperature compensation optimize battery charging and increase the battery’s life

- Allows simultaneous connection of two charging sources (e.g., solar panel, ac wall charger)

Images

3D/CAD Files:

Related Products

Technical Description

The PS200 power supply consists of a rechargeable, 7 A h, valve-regulated lead-acid (VRLA) battery and a charging regulator. This microcontroller-based smart charger has two-step constant voltage charging and temperature compensation that optimize battery charging and increase the battery’s life.

Two input terminals enable simultaneous connection of two charging sources. The PS200 also incorporates a maximum power point tracking algorithm for solar inputs that maximize available solar charging resources. RS-232 and SDI-12 terminals allow the PS200 to convey charging parameters to a datalogger.

The PS200 has several safety features intended to protect the charging source, battery, charger, and load devices. Both the SOLAR – G and CHARGE – CHARGE input terminals incorporate hardware current limits and polarity-reversal protection.

A fail-safe, self-resettable thermal fuse protects the CHARGE – CHARGE inputs in the event of a catastrophic AC/AC or AC/DC charging source failure. Another self-resettable thermal fuse protects the 12 V output terminals of the charger in the event of an output load fault.

The PS200 also has battery-reversal protection, and includes ESD and surge protection on all of its inputs and outputs.

Specifications

| Operational Temperature | -40° to +60°C (VRLA battery manufacturers state that “heat kills batteries” and recommend operating batteries at ≤ 50°C.) |

| Dimensions | 19 x 7.6 x 10.6 cm (7.5 x 3 x 4.2 in.) |

CHARGE - CHARGE Terminals (AC or DC Source) |

|

| AC | 18 to 24 VRMS (with 1.2 ARMS maximum) |

| DC | 16 to 40 Vdc (with 1.1 Adc maximum) |

SOLAR Terminals (Solar Panel or Other DC Source) |

|

| -NOTE- | Battery voltages below 8.7 V may result in less than 3.0 A current limit because of fold-back current limit. |

| Input Voltage Range | 15 to 40 Vdc |

| Maximum Charging Current | 4.0 Adc typical (3.2 to 4.9 Adc depending upon individual charger) |

Quiescent Current |

|

| No Charge Source Present | 300 μA maximum |

| No Battery Connected | 2 mA maximum |

Battery Charging |

|

| -NOTE- | Two-step temperature-compensated constant-voltage charging for valve-regulated lead-acid batteries; cycle and float charging voltage parameters are programmable with the default values listed. |

| CYCLE Charging | Vbatt(T) = 14.70 V - (24 mV) x (T-25°C) |

| FLOAT Charging | Vbatt(T) = 13.65 V - (18 mV) x (T-25°C) |

| Accuracy | ±1% (on charging voltage over -40° to +60°C) |

Power Out (+12 Terminals) |

|

| Voltage | Unregulated 12 V from battery |

| 4 A Self-Resettable Thermal Fuse Hold Current Limit |

|

Measurements |

|

| -NOTE- | At -40° to +60°C |

| Average Battery Voltage | ±(1% of reading + 15 mV) |

| Average Battery/Load Current Regulator Input Voltage |

±(2% of reading + 2 mA) Impulse type changes in current may have an average current error of ±(10% of reading + 2 mA). |

| Solar |

±(1% of reading - 0.25 V) / -(1% of reading + 1 V) 1.0 V negative offset is worst-case due to reversal protection diode on input; typical diode drop is 0.35 V. |

| Continuous |

±(1% of reading - 0.5 V) / -(1% of reading + 2 V) 2.0 V negative offset is worst-case due to two series diodes in AC full-bridge. Typical diode drops are 0.35 each for 0.7 V total. |

| Charger Temperature | ± 2°C |

Related Documents

Downloads

PS200 Example Programs v.1.1 (36.4 KB) 08-12-2014

CR1000 programming examples for use with the PS200. The examples show how to use both SDI-12 and RS-232 advanced instruction programming techniques.

CH200 / PS200 OS v.11 (434 KB) 24-04-2020

Execution of this download installs the CH200 / PS200 Operating System on your computer.

Note: The Device Configuration Utility is used to upload the included operating system to the CH200 / PS200.

Related FAQs

Number of FAQs related to PS200: 8

Expand AllCollapse All

-

Yes. The G and 12V terminals on the charge regulator are used to connect the black and red wires that connect with the green connector, which provides power to the data logger.

-

The voltage from a solar panel will fluctuate throughout the day.

If AC power is being used, the voltage is usually stable.

The voltages coming into the regulator inputs are controlled so that the battery won’t be overcharged (and thus ruined by boiling out the electrolyte). If the battery connected to the regulator is good, the highest voltage you will likely see is just above 14 Vdc in the extreme cold, but normally it should be around 13.2 Vdc.

If you have a nearly dead battery (to be checked with a voltmeter) or a battery with shorted cells, you will see a very low battery voltage. The lowest voltage you will see on the data logger data is usually about 10.0 V because the data logger will shut down near that level and then wait for the voltage to increase to an 11- or 12-volt level.

The ripple voltage is a few millivolts flowing into the battery, but the battery should filter out most of that noise, providing a pretty stable voltage.

-

The PS100, PS150, and PS200 models take in AC or DC power from a wall transformer or a solar panel. The internal regulator controls the charge to the battery to make sure the battery doesn’t become overcharged (based on temperature).

If the switch is on, the voltage from the battery will flow back out from the regulated battery to the loads; however, the voltage on that battery may be 11.9 V, 13.2 V, or some other value that the battery happens to be at. It is important to understand that the voltage will not always be exactly 12.0 Vdc. Rather, the voltage will float up or down as the battery is recharged or depleted.

-

Look for a stamp on top of the battery. The stamp may be in a date format of YYMMDDXX where:

- YY is the year.

- MM is the month.

- DD is the day.

- XX is the manufacturing plant.

This indicates the age of the battery.

-

Battery manufacturers recommend that their batteries be charged at least once every 3 to 6 months. If an extra wall charger is available, such as a 29796, Campbell Scientific recommends keeping it continually connected to ac power.

-

The PS100 is a float-only charger that is limited to a 20 W solar panel and a maximum load of approximately 1 A.

The more advanced (and more expensive) PS200 is a multistage controller that can charge at higher rates and use larger solar panels (90 W) while delivering a maximum of approximately 4 A to the load, depending on the temperature. The PS200 is a smart charger that incorporates MPPT (maximum power point tracking) technology and can be interrogated by the datalogger to check its state, solar panel status, load currents, battery voltage, and net battery current. In this regard, the PS200 acts as a high-tech sensor, as well as a charge regulator.

The PS100 has a temperature sensor for temperature compensation. The PS200 has a similar onboard temperature sensor, but it is more efficient and does not dissipate as much heat with a similar load. The PS200 also has a feature where an independent battery temperature measurement can be sent to the charger rather than using its onboard temperature sensor.

-

The SP20 or SP20-PW solar panels can be connected in parallel (not series) to get more energy out during the day, or to extend the hours of charging (one facing east and one facing west). To accomplish this using a PS100/CH100, use the full-bridge diodes inside the PS100/CH100 as blocking diodes to prevent a shaded panel from loading down a non-shaded panel. Note that the PS100 charging current is limited to 1.2 A, thus the full benefit of both panels in full sun may not be realized.

- Connect the two separate positive outputs to the two separate charge inputs.

- Connect both return wires to the PS100/CH100 ground terminals.

The diagram below illustrates how to connect two 20 W panels:

Another method, using two blocking diodes, can be used with the PS200/CH200 charge controller:

For more information, contact an application engineer at Campbell Scientific.

-

The operating voltage is 9.6 to 16 Vdc. The datalogger will shut down at 9.6 Vdc. When this happens, a counter is incremented in the datalogger Status table (low12Vcount). In general, 12 to 14 Vdc is a normal range. Voltages above 16 Vdc could damage the datalogger and cause bad measurements. Therefore, the resulting data should be reviewed carefully. Sustained voltages in excess of 16 Vdc can damage the datalogger and the wiring panel.